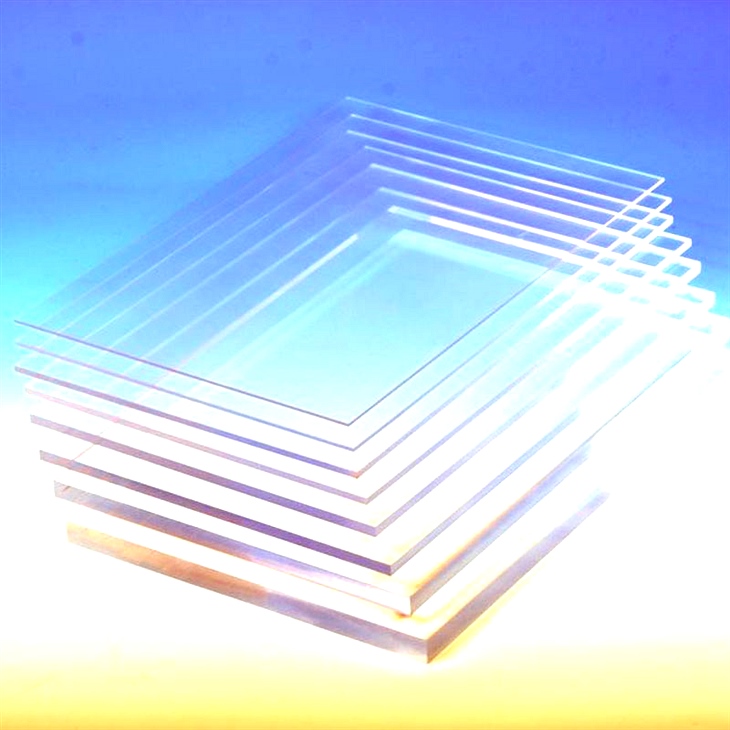

Acrylic flame retardant board

Flame-retardant board is a kind of flame-retardant functional acrylic board, transparent or colored, flame retardant grade reaches UL94-V0 level, excellent light transmission, no warpage of the board surface, commonly used in petrol stations, workshops, airports, shopping malls, and household appliances , Exhibitions, buildings and other places that require fire protection.

Product description

Flame-retardant board is a kind of flame-retardant functional acrylic board, transparent or colored, flame retardant grade reaches UL94-V0 level, excellent light transmission, no warpage of the board surface, commonly used in petrol stations, workshops, airports, shopping malls, and household appliances , Exhibitions, buildings and other places that require fire protection.

Thickness: 3mm-10mm

Specification: common size 1220×1830mm, 1220*2440mm, 2050*3050mm

Other sizes can be consulted, support customized sizes

Application industries: construction, industrial workshops, ships, decoration, lighting, gas stations, chemical industry, instrumentation and other industries that require fire protection and explosion protection

Product Features:

(1) Good light transmission

(2) Even flame retardant

(3) Good weather resistance

(4) Customizable colors

(5) Good mechanical properties

At present, this kind of flame-retardant acrylic is widely used in the market. Today I will take you to understand it.

It is necessary to know that the bonding of acrylic flame retardant is a very critical process in acrylic processing. How to show the clear and transparent characteristics of plexiglass, reflect the value of acrylic tobacco and alcohol packaging crafts, and maximize the grade and taste of acrylic crafts. The connection technology played a pivotal role.

The adhesion of plexiglass plates is mainly affected by two aspects, one is the applicability of the adhesive itself; the other is the bonding skills.

There are many adhesives in the domestic and foreign markets, there are mainly two types, one is two-component, such as universal glue, epoxy resin; the other is one-component, such as CHCl3 (chloroform). Generally speaking, two-component adhesives are bonded through curing reaction, and single-component adhesives are the final volatilization of a solvent to achieve bonding.

Before bonding, it is recommended to understand the basic bonding steps and make sufficient preparations to ensure correct bonding.